For Which Of The Following Should We Use An R-chart To Monitor Process Quality?

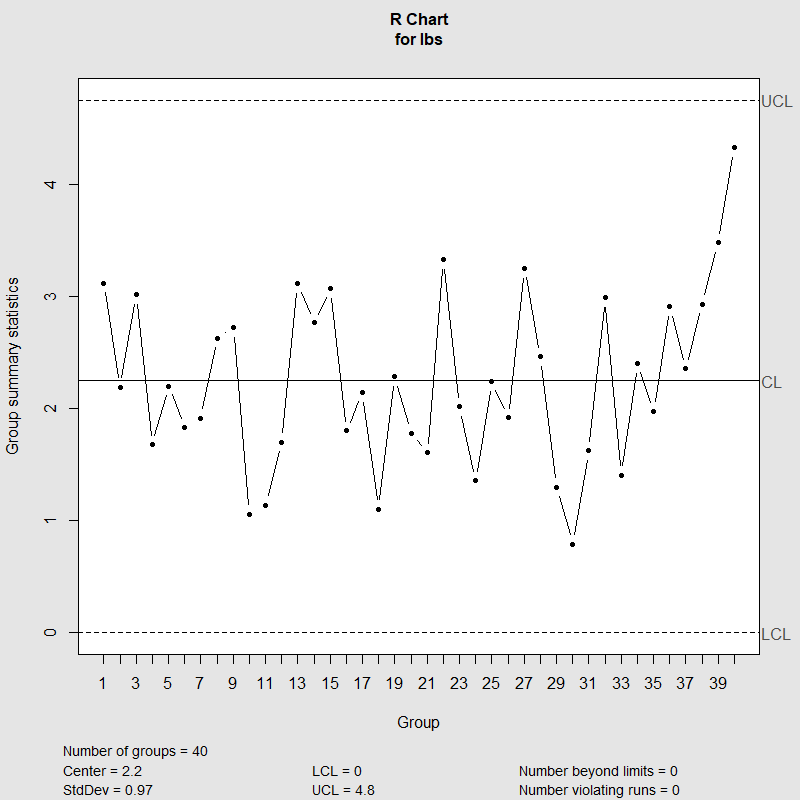

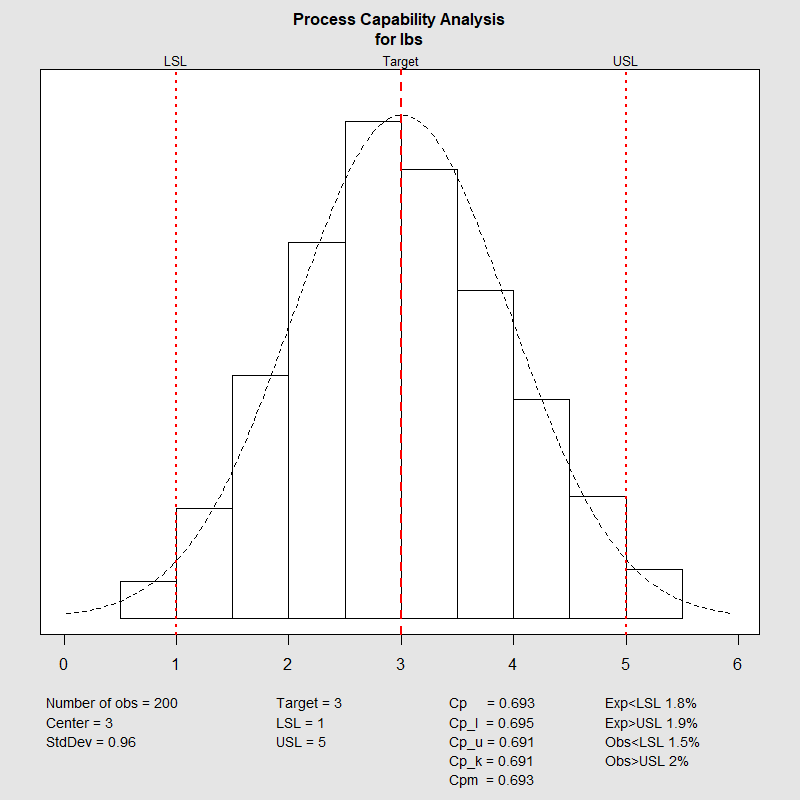

Typically an initial series of subgroups is used to estimate the standard deviation of a process.

For which of the following should we use an r-chart to monitor process quality?. With which of the following should we use an X-bar chart based on sample means to monitor. Determining the accuracy of a forecast of snow. Tire pressures in an auto.

The standard deviation is then used to produce. There are very few times when you should start to. If youre looking at measurement data for individuals you would use an I-MR chart.

Determining whether vehicles from a motor pool will run. For which of the following should we use a p chart to monitor process quality. The second referred to as a multivariate control chart is a graphical display of a statistic that summarizes.

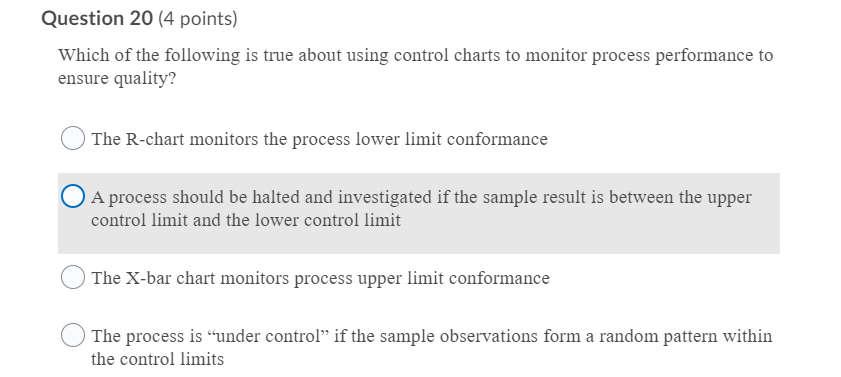

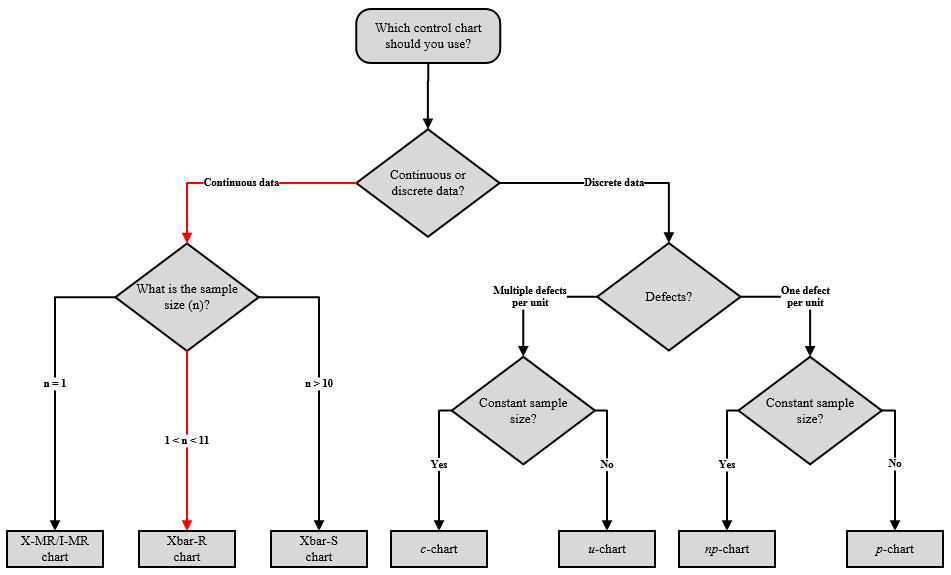

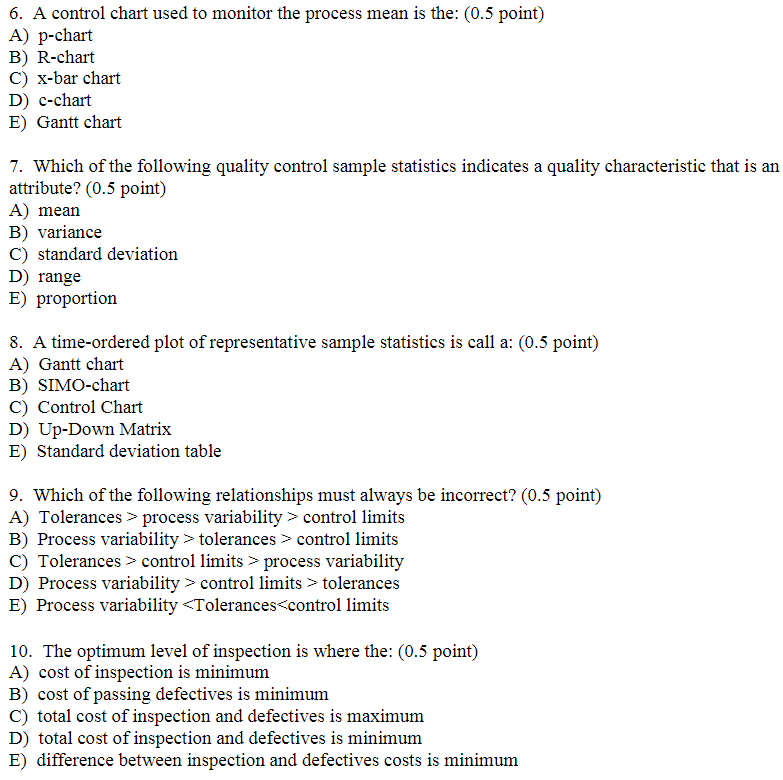

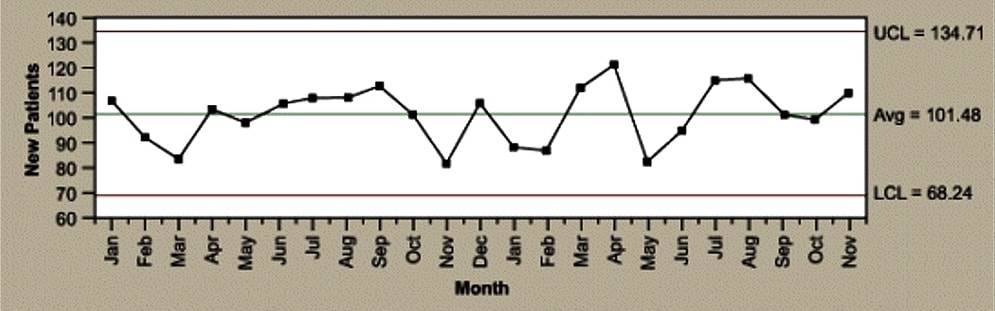

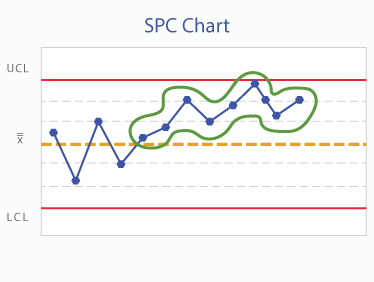

The process mean is the center line and if this isnt specified then. Depending on the number of process characteristics to be monitored there are two basic types of control charts. Control charts are used to routinely monitor quality.

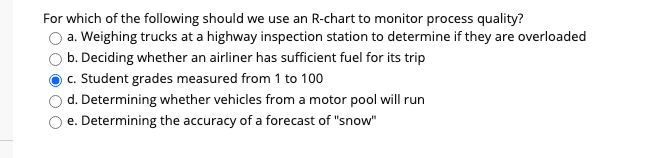

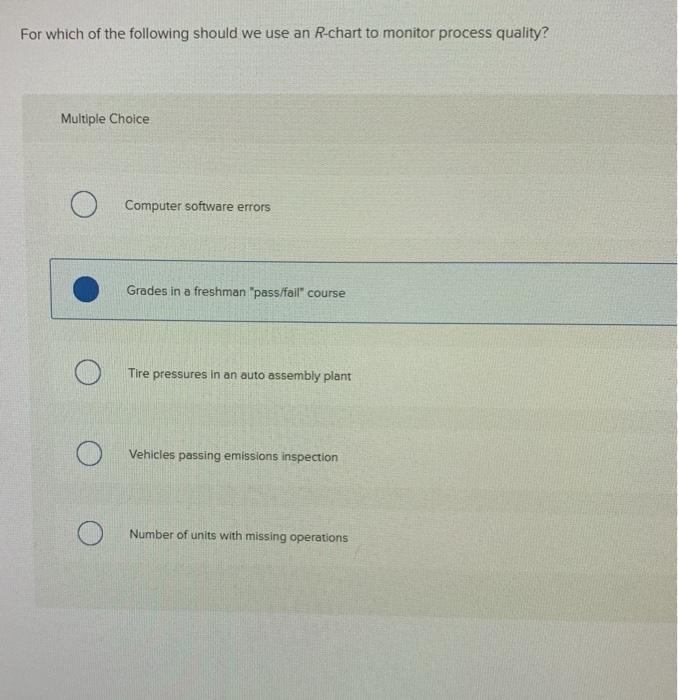

Vehicles passing emissions inspection Computer software errors Number of units with missing operations Grades in a freshman passfail course Tire pressures in an auto assembly plant 15. Deciding whether an airliner has sufficient fuel for its trip C. Weighing trucks at a highway inspection station to determine if they are overloaded B.

Grades in a freshman passfail course. Deciding whether an airliner has sufficient fuel for its trip C. For which of the following should we use a p chart to monitor process quality 1.

Student grades measured from 1 to 100 D. Each point on the chart acts as a subgroup mean value. Weight height width time and similar measurements are all continuous data.

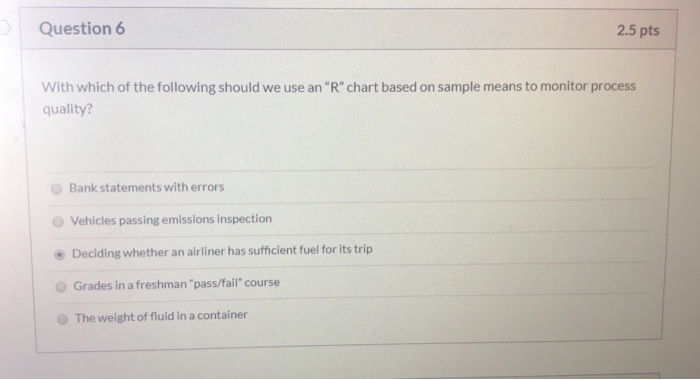

Which of the following should we use an R chart to monitor process quality. Bank statements with errors Vehicles passing emissions inspection Deciding whether an airliner has sufficient fuel for its trip Grades in a freshman passfail course The weight of fluid in a container. X bar R chart is used to monitor the process performance of a continuous data and the data to be collected in subgroups at a set time periods.

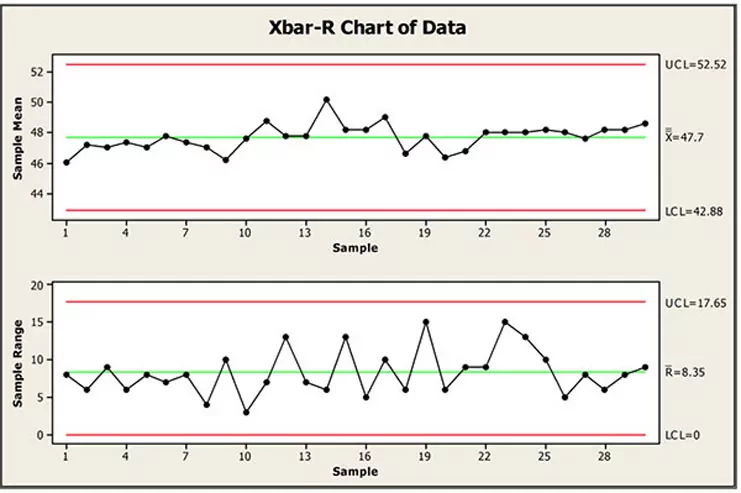

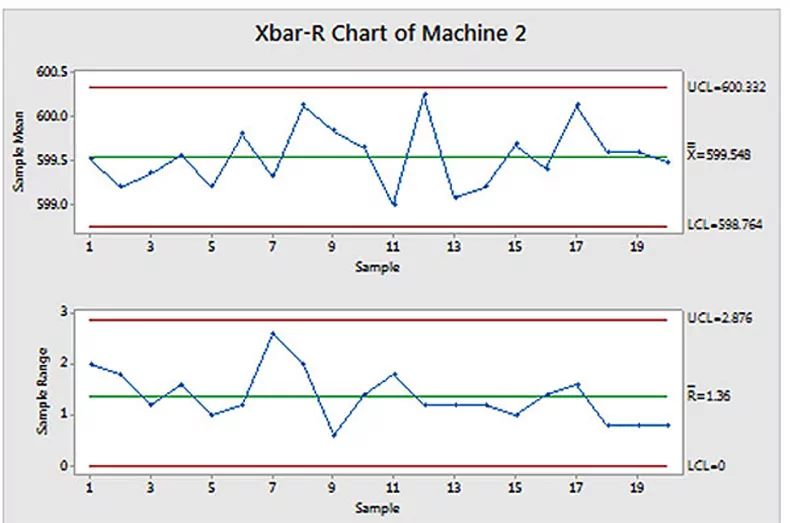

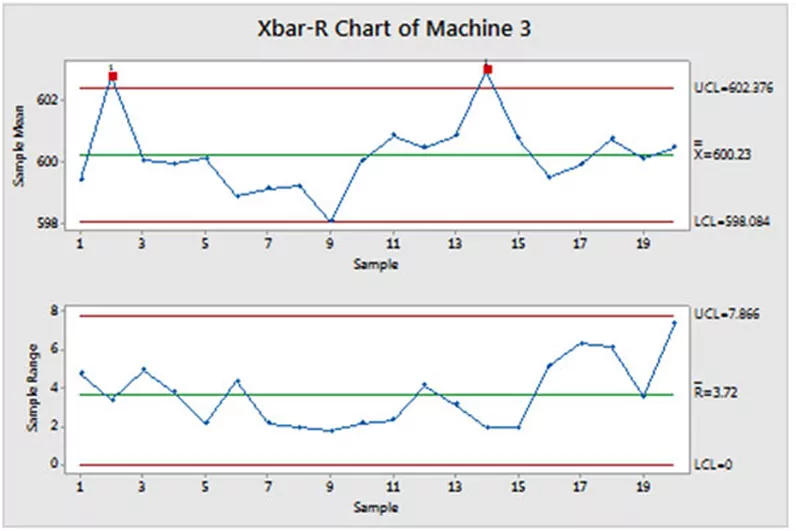

The X-Bar Chart is typically combined with an R-Chart to monitor process variables. Deciding whether an airliner has sufficient fuel for its trip C. The control limits on both chats are used to monitor the mean and variation of the process going forward.

Student grades measured from 1 to 100 D. It is actually a two plots to monitor the process mean and the process variation over the time and is an example of statistical process control. For which of the following should we use a p chart to monitor process quality.

Determining whether vehicles from a motor pool will run. If the variable isnt under control then control limits might be too general which means that causes of variation that are affecting the process mean cant be pinpointed. Student grades measured from 1 to 100 D.

With which of the following should we use an X-bar chart based on sample means to monitor process quality. Weighing trucks at a highway inspection station to determine if they are overloaded B. Determining whether vehicles from a motor pool will run E.

Weighing trucks at a highway inspection station to determine if they are overloaded B. The measurements of the samples at a given time constitute a subgroup. Which of the following should we use an R chart to monitor process quality.

R charts are used to monitor the variation of a process based on samples taken from the process at given times hours shifts days weeks months etc. It is often used to monitor the variables data but the performance of the and R. The first referred to as a univariate control chart is a graphical display chart of one quality characteristic.

If your data are being collected in subgroups you would use an Xbar-R chart if the subgroups have a size of 8 or less or an Xbar-S chart if the subgroup size is larger than 8. For which of the following should we use an R-chart to monitor process quality. A Lengths of boards cut in a mill b The weight of fluid in a container c Temperatures in a classroom d The dimensions of brick entering a kiln e Grades in a freshman passfail course.

If a point is out of the control limits it indicates that the mean or variation of the process is out-of-control. If a point is out of the control limits it indicates that the mean or variation of the process is out-of-control. The control limits on both chats are used to monitor the mean and variation of the process going forward.

Question 6 25 pts With which of the following should we use an Rchart based on sample means to monitor process quality. The x-bar and s-chart are quality control charts used to monitor the mean and variation of a process based on samples taken in a given time. The x-bar and R-chart are quality control charts used to monitor the mean and variation of a process based on samples taken in a given time.

In statistical process monitoring SPM the and R chart is a type of scheme popularly known as control chart used to monitor the mean and range of a normally distributed variables simultaneously when samples are collected at regular intervals from a business or industrial process.