Drill Bit Sharpening Angle Chart

Sharpen two primary clearance angles.

Drill bit sharpening angle chart. 17 Sharpening Drill Bits. This condition is a unique property of the Tangent function. If you start to rotate the bit around the axis of the cone on the rear face will be formed a conical surface.

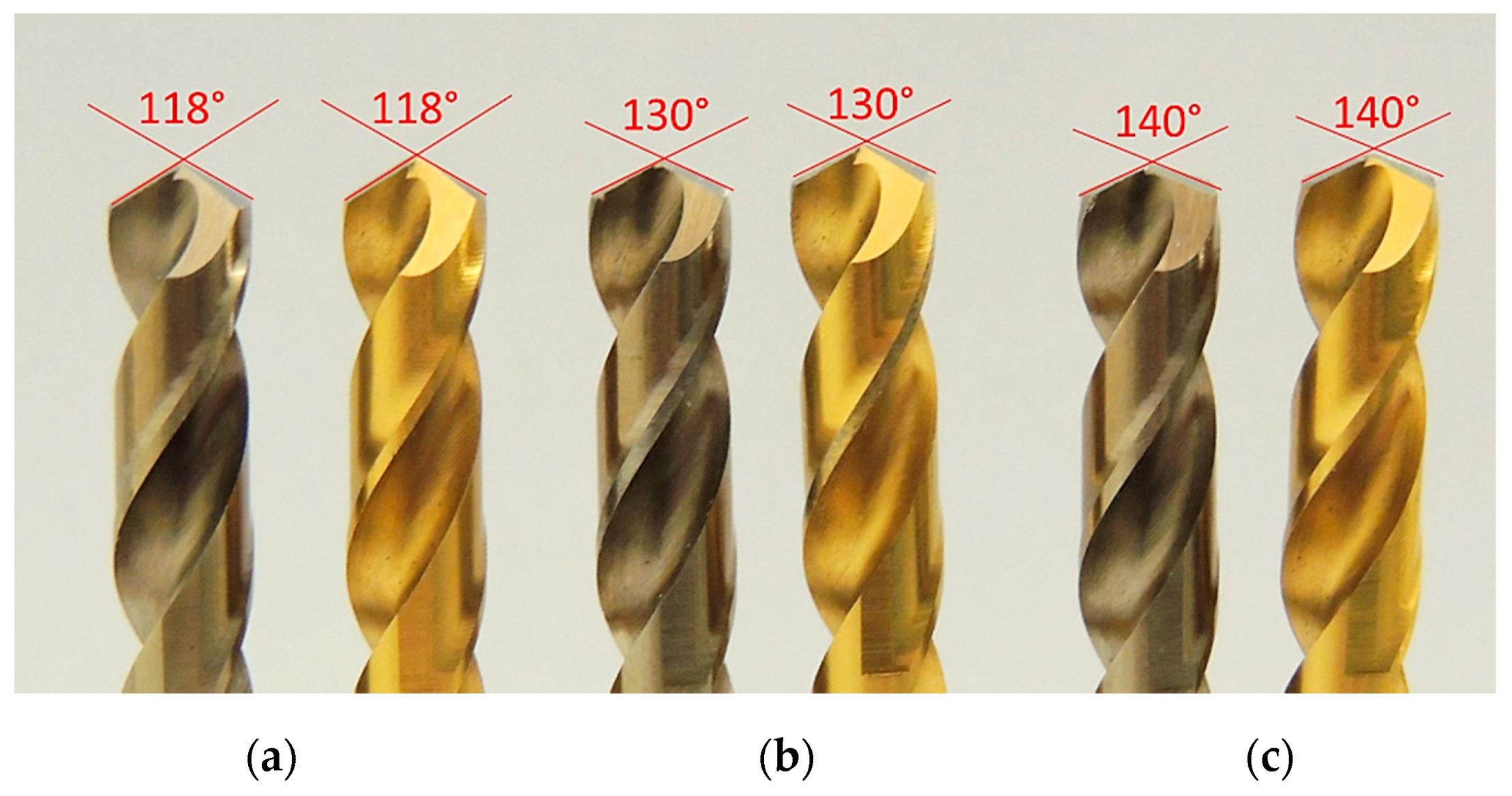

Multiplied by both cutting edges the 1 drill with 118 included angles is the equivalent of drilling with a 332 larger diameter drill. Simply it is the angle between the lips in the side view of a twist drill. Step 2 Line Drill up with Gage against desired Tip Angle.

Drill bits axis should intersect with the axis of the imaginary cone at an angle of approximately 45. To reduce risk of injury the user must read and understand this instruction. The edge at the end of the web that connects the cutting lips.

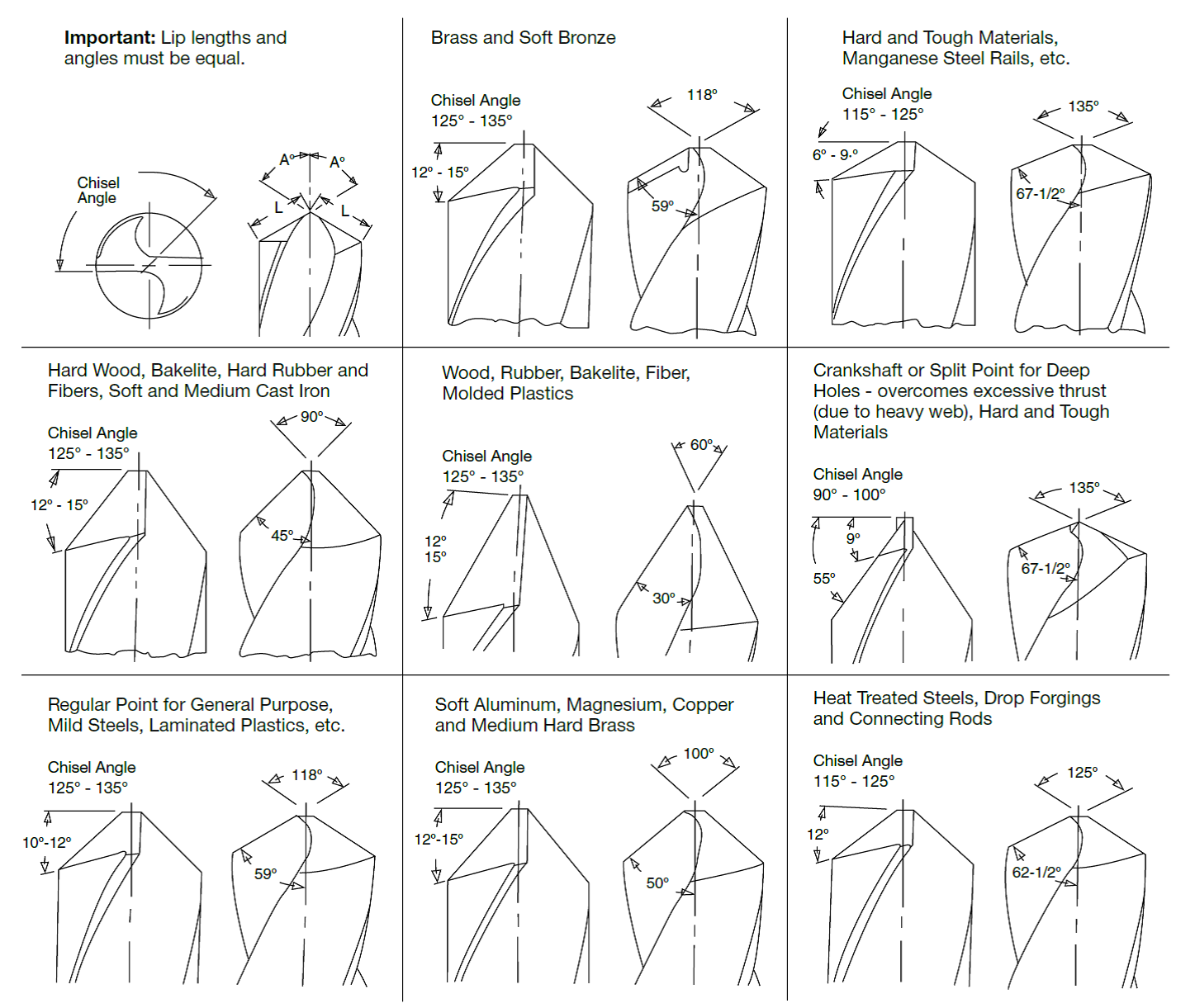

In this video I show you a possible to angle a drill bit without official equipment. Be used for finishing. 135 135 - 140 7 6 - 9.

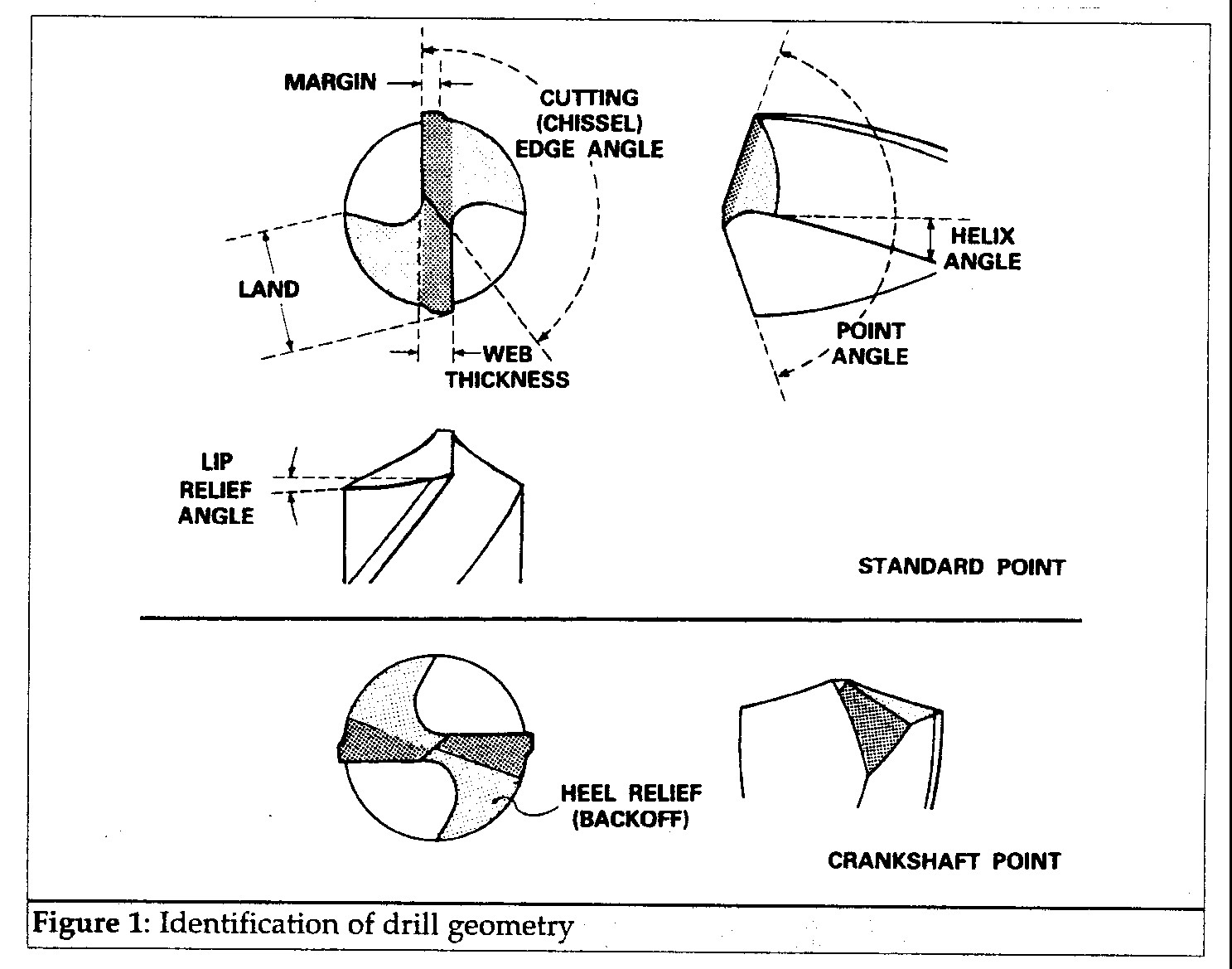

How to sharpen a drill bit. Clearance angles based on drill bit size should be used. So that two Major Cutting Lips should be symmetrical the Major Cutting Lips have the same included angle with the spindle axis of twist drill and the lengths are same.

By Craig Kirkman For more useful information please take a look at my website. On approaching the drill center the angle becomes very severe very quickly. 17 Aligning the Drill Bit.

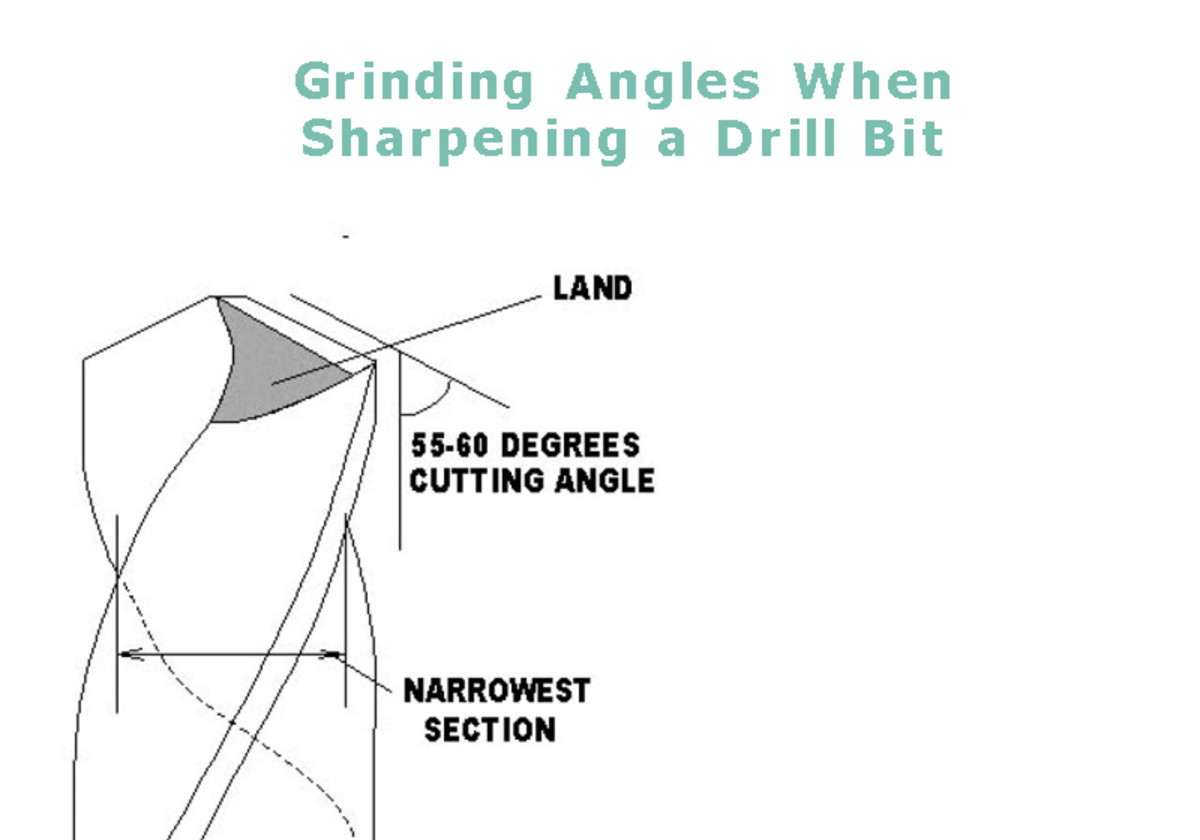

Resharpening of the twist drill bits To get a good performance from a drill bit the sharpening must be done correctly this. Both cutting edges are sharpened at the same angle so each makes angle of 59 to the center axis. Take the desired file for sharpening the drill bit.

Drill Diameter Range Lip Relief Angle 80 to 61 24 60 to 41 21 40 to 31 18 18 to 14 16 F to 1132 14 S to 12 12 3364 to 34 10 4964 and larger 8. Step 3 Drill Test and the Effects of incorrect grinding of the Drill Point. How to sharpen and touch up drill and auger bits.

Review the figure a. The vertex is placed as shown at the picture. Specifically the lip length of a 1 diameter drill with 140 included angles will measure 916 per lip and the same drill with 118 included angles will measure 3964 length per lip.

Relief angles of from four to six degrees depending on the material. In this case the angle at the tip should be equal to 26. To these helix angles we also must add proper relief for clearance.

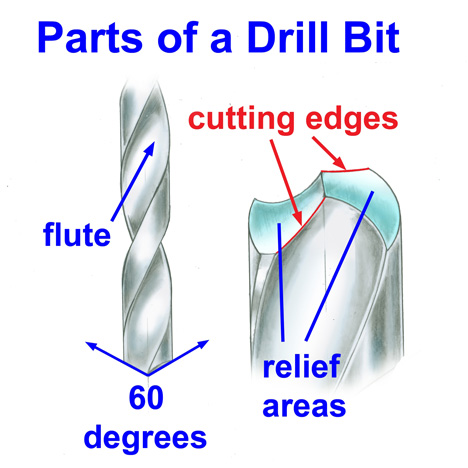

The helical groove in the drill bit is called the flute. We will file each of the relief areas to sharpen the drill bit maintaining the same angle as these planes which is important for the drill bit to perform properly after sharpening. The DRILL POINT SHARPENING GAGE is the tool most frequently used to check the drill point during the sharpening operation.

Please read the Disclai. Part of the Workshop Companion a collection of information on wood woodwork woodworking skills woodworking materials and woodworking plans that together form the core knowledge needed by woodworkers furniture makers cabinetmakers turners and other practioners of the wood arts to become competent craftsmen. Choosing Your Drill Bit Point Angle on the Model DD500X.

N4-Variation of lip relief angle achieved with the sharpening method Cawi-Spiral Se ction A-A Se B- Section C-C Section D-D Section E-During re-sharpening is necessary to observe certain precautions to prevent structural changes or other incidents at. Cutting angle Point angle The cutting angle is the angle between two lips when it is projected on a plane parallel to the axis. I have used this method for a number of years so i thought I would shar.

Difficultly should be ensure the clearance angle point angle and flank angle of chisel edge are correct. THE DRILL BIT SHARPENER USER GUIDE GET SHARP AND GET BACK TO WORK Caution. Drill bit angle and speed chart.

The helix angle reaches NINETY degrees at the drill center. With larger drills the spread is markedly increased. Hold the one side of the file making a.