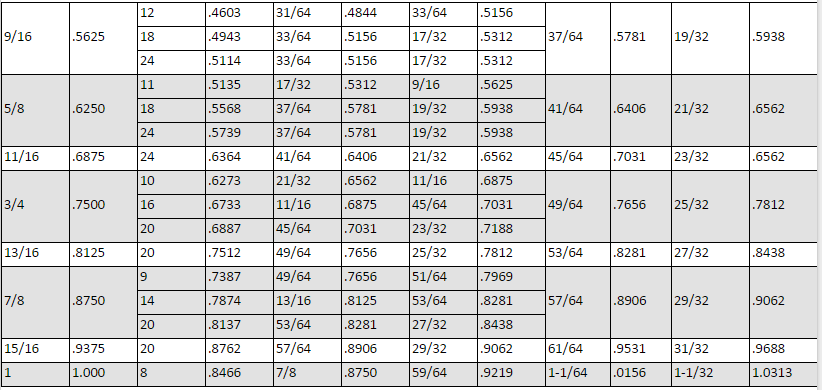

Speed And Feed Chart

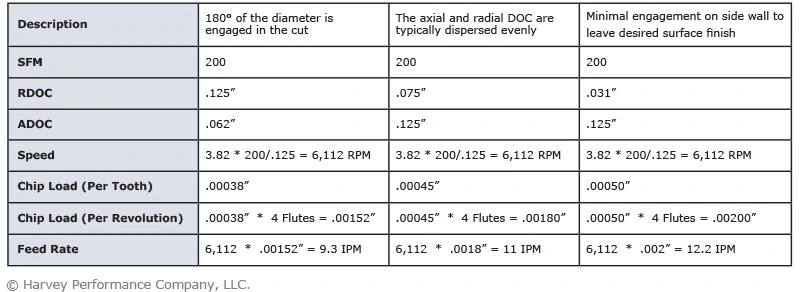

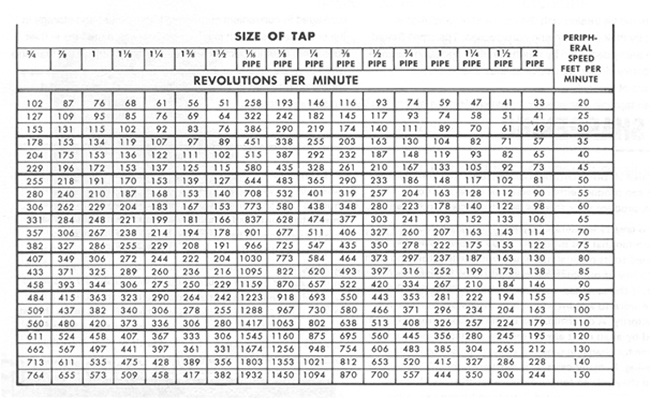

First is the formula to find the RPM RPM SFM X 382 diameter of the tool SFM Surface Feet per Minute You can also use the RPM calculator below.

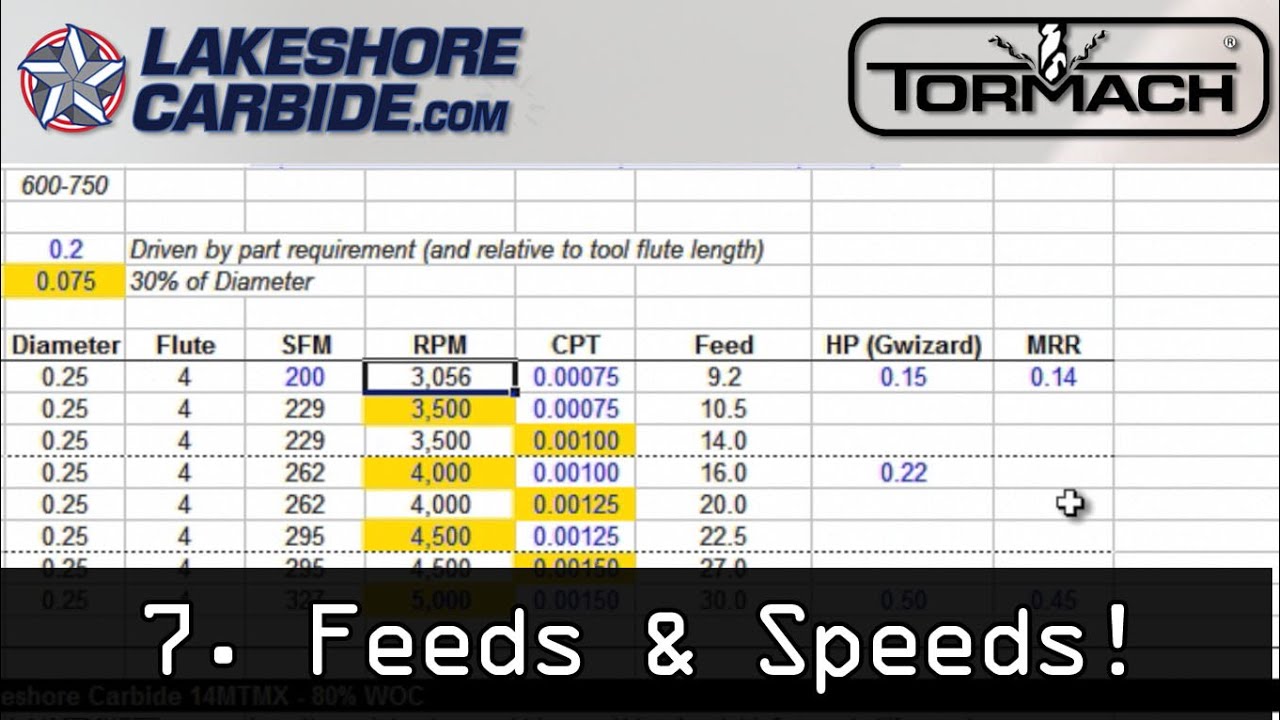

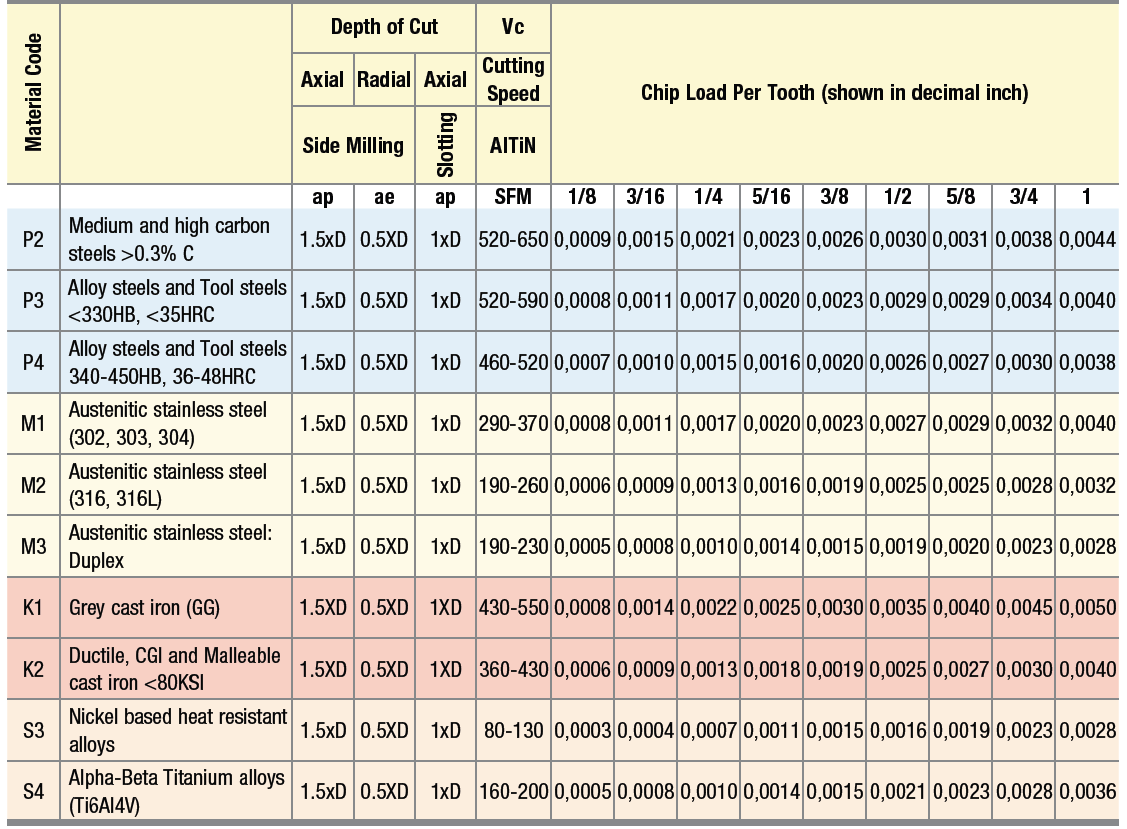

Speed and feed chart. Feed Control Milling Customize how the Feeds and Speeds Calculator fine-tunes the Chip Load and Table Feed. Radial Depth of Cut Ae Depends on how you plan to prefoprm your application. These calculations are based upon theoretical values and are only intended for planning purposes.

Machine Tool Speeds and Feeds. Therefore it only covers 2 variables. SMM surface meters per minute.

Whith the above parmeters you can proceed to calculate the Milling Feed Table Feed. Start off using an RPM derived for the chip load for the. Calculate the Chip Thinning factors in order to get the Feed per Tooth.

Table Feed RateFv mmmin. They use multiple charts add columns and rules of thumb to cover a few more variablesmaybe 4 to 6. In the case of 90 cutters taking a radial depth of more than 50 of the cutters diameter the chip load is exactly the.

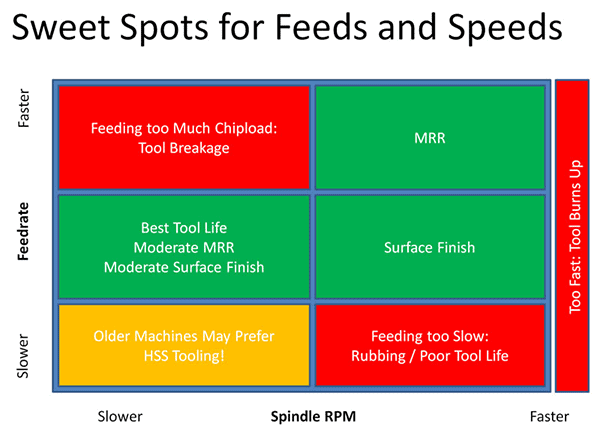

The phrase speeds and feeds or feeds and speeds refers to two separate velocities in machine tool practice cutting speed and feed rate. Milling Speeds and Feeds. Feeds and speeds formula.

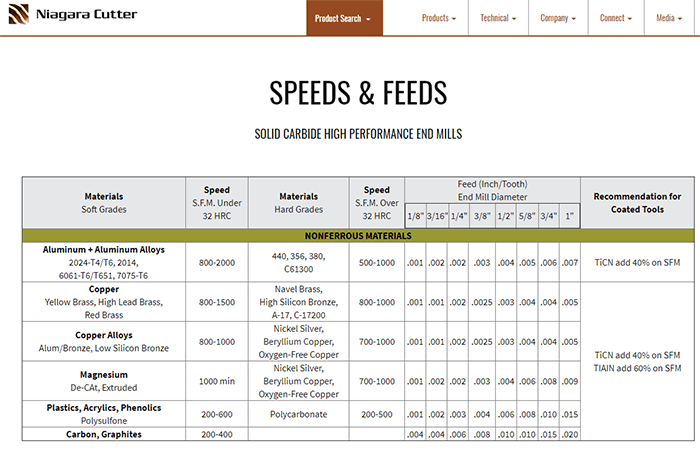

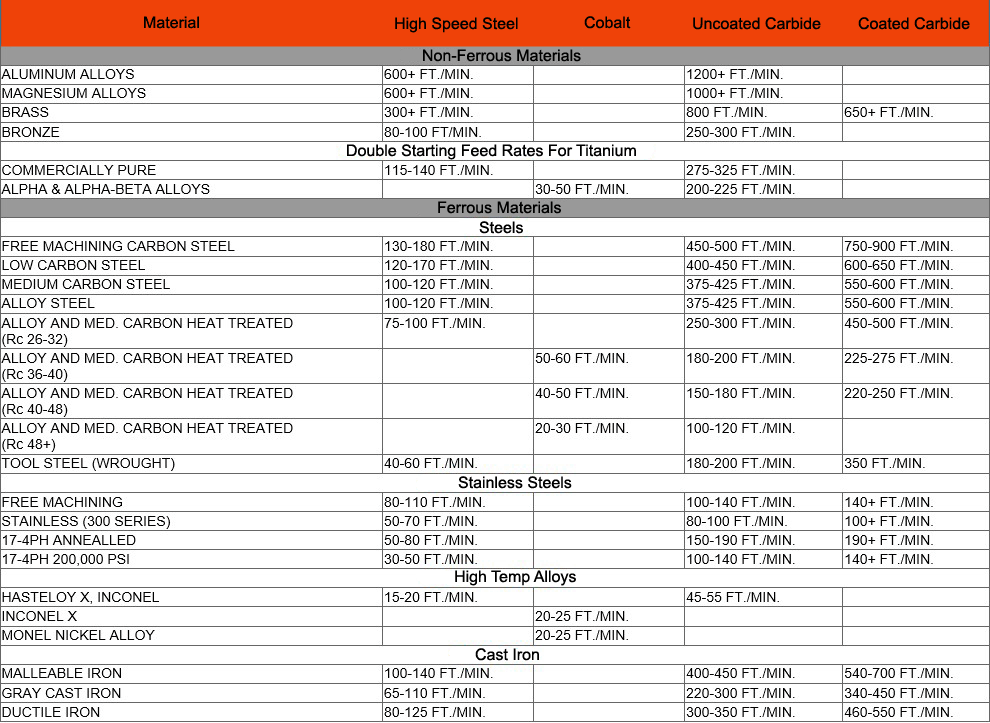

Thats a database and the best calculators will make it possible to calibrate that database with your experience your tooling and your shops best practices. End Mill Speeds and Feeds Calculator Milling Feeds and Speeds Spindle Speed Calculator. Recommended Speeds sfpma Material Drill Lathe Mill Magnesium 300 400-800 200-400 Aluminum 250 350-700 250-500 Brass Bronze 200 250-500 150-450 Copper 70 100-250 100-200 Cast Iron soft 120 100-250 80-120 Cast Iron hard 80 50-150 50-100 Mild Steel 110 100-250 70-120 Cast Steel 50.

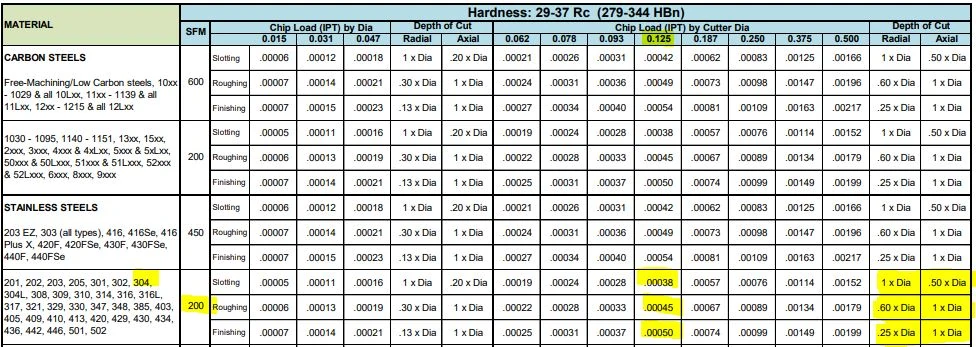

TITANIUM DOUBLE STARTING FEED RATES COMMERCIALLY. This chart provides starting parameters for calculating speeds and feeds. RPM SMM X 31806 Tool.

Spindle speed RPM Feed rate IPM. The Speeds and Feeds Calculator uses the following formulas. Factors such as machine fixture and tooling rigidity horsepower available coolant.

9 rows Optimizing feed rates and speeds. The Chip Thinning factors make. Spindle RPM Formula 12 SurfacceSpeed PI CutterDiameter Feed Rate Calculator.

Next the formula for the feedrate uses the RPM from the previous calculation Feedrate RPM X Feed per tooth X Number of teeth. Each however can also be considered and analyzed in its own right. RPM 12 Surface Speed PI Tool Diameter revsmin Feed Rate RPM Chip Load Number of Teeth Flutes inmin Where PI is the constant 3141592654.

Drilling Speeds and Feeds. Cutting Speed Get wit with our Speeds and Feeds Calculator or from the tool suppliers catalogwebsite. Feed per tooth IPT.

Tool Diameter inches. 31 rows Speeds - Metric. Reaming Speeds and Feeds.

A feeds and speeds calculator starts with its own internal tables of what the chiploads surface speeds tweaks for different materials and all the rest should be. Keyseat Cutter Speeds and Feeds. High Speed Steel Cobalt Tool Steel Uncoated Carbide.

Cutting speed is the speed difference between the cutting tool and the surface of. Below are the Speeds and Feeds Charts for Rock River Tool products. A basic Feeds and Speeds Chart like whats in your tooling catalog is a 2 dimensional entity.

SFM see table below for SFM values Spindle Speed. Milling Speeds Feeds Calculator. Speed and Feed Calculator for Miscellaneous Applications.

IPT inches tooth. Number of TeethZ Feed per toothFz mmtooth. Feeds and speeds are starting recommendations only.

Machine Tool Speeds and Feeds. Tool diameter in π Spindle speed RPM Cutting feed IPR. The Chip Load Maximum chip thickness is the largest chip that a cutting edge can handle without breaking and still maintain decent tool-life.

Counterboring Speeds and Feeds.